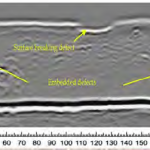

- A virtual replacement for Radiography (Cross sectional view of the weld as below)

- TOFD is safer than Radiography testing and more environmentally friendly.

- Because No Ionizing radiation is required, the inspection does not interfere with the production process. TOFD inspections can therefore take place in parallel to production work.

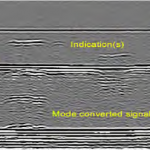

- TOFD known to generally allow for better weld defect identification, location and accurate sizing.

- TOFD has High probability of detection (POD), Low False Call Rate, High accuracy in flaw sizing.

- The TOFD technique is a fully computerized and automated system able to scan, store, and evaluate indications in terms of height, length, and position with a grade of accuracy never achieved by other ultrasonic techniques.

- Thicknesses within the range of 6 to 450 mm can be examined.

- TOFD examinations are possible to temperatures of up to 250ºC.

- Acceptable to ASME Sec VIII (Pressure Vessels) & ANSI B 31.3 (Piping) in lieu of Radiography