Destructive tests are carried out in the laboratory for specific application in close association with international client specifications on materials & welded specimens. Materials shall be certified for grade confirmation based on the evaluation of the test results. Welder performances are evaluated and certified & welding procedures are qualified by incorporating inspection, NDT & mechanical tests in accordance with international standards and client’s requirements. We carry out various mechanical tests like tensile test to find out the physical properties namely yield strength, tensile strength, elongation, reduction of area etc, Charpy impact test on full & sub size specimens to verify the toughness of material, hardness tests- Vickers, Rockwell, Brinell, Knoop at lab and at site, nick break test on materials and weldments. Macro examination of welded specimens is also carried out.

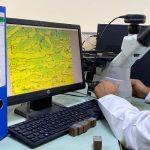

We also perform metallographic test for close scrutiny of metallurgical structures of samples by evaluating the microstructure to establish phases on etching and their morphology. Grain size measurement & ferrite content shall be determined by evaluating the microstructure which will be reported with photographic proof.

Replica technique is used for metallurgical services at site applications particularly for boiler tubes, heat exchanger tubes etc.

Other corrosion tests to check susceptibility to intergranular corrosion, pitting corrosion, hydrogen induced, stress corrosion cracking under Sulphide, chloride atmospheres. Chemical analysis is carried out using wet method or atomic absorption (spectrometer) to determine the percentage of chemical elements present in metals.

The major activities are as listed below:

- Tensile Test at ambient temperatures and elevated temperatures (upto 700 deg C)

- Bend / Embrittlement / Rebend Test

- Charpy Impact Test at cryogenic temperatures (upto -196 Deg C)

- Compression Test

- Load Test – Proof load test

- Fracture Test

- Macro & Micro Examination/Analysis

- Ferrite Testing by manual & Ferritescope.

- Hardness Test- Vickers, Rockwell, Brinell

- Metallographic Evaluation using Replica Technique

- Grain size measurement

- Chemical Analysis- Using Spectrometer & Wet method

- Corrosion tests- HIC, SSCC, Pitting, Intergranular corrosion

- Failure Investigation

Investigations on the cause of failure on various engineering components are carried out which is applicable in marine, industrial and oilfield sectors and are very significant for decisions on preventive measures, corrective action and future modifications. The findings on investigation of the cause of failure & the remedial recommendations by our qualified metallurgist will be reported.